The Covid-19 disease has affected a variety of sectors of society. the slow return to normalcy has come with back-slashes. The most notable of these is the US automobile market which is required to in addition reduce production and lay off workers. At the heart of this turmoil is a small piece is likely to be in your hand or your pocket right now which is the microchip.

The worldwide shortage of chips that resulted from the Covid epidemic has affected everyone even remotely associated with the auto industry. From drivers seeking for a replacement to the Toyota Camry to workers in factories who is responsible for assembling seats in the Chevy Silverado. Why? because it has caused an extended interruption in the production of vehicles–the kind of disruption that can cause a negative impact on everyday life.

What Are Chips?

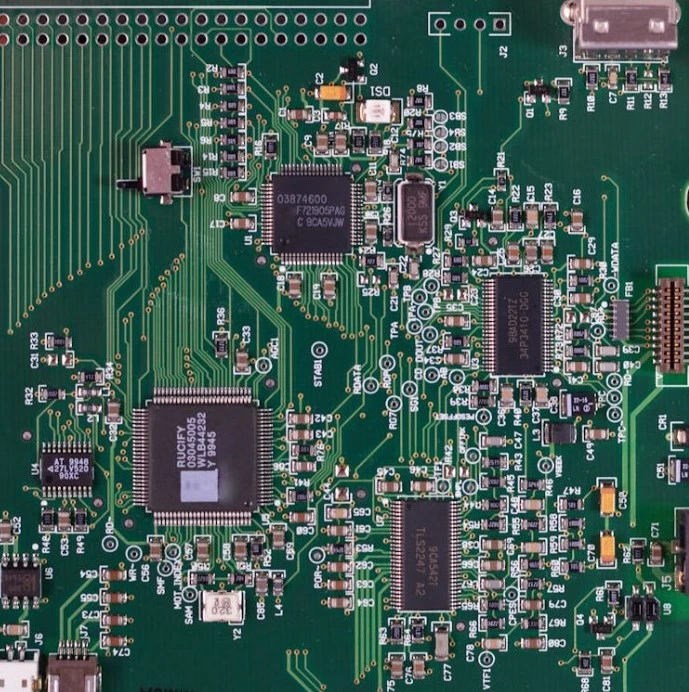

When we think of car parts most of the items that pop up include likely brakes, tires or wipers, or other component that usually requires repairs or maintenance during the ownership. However, in more advanced vehicles it is possible that we will be having to upgrade an infotainment system and tire-pressure sensors, parking sensors or and perhaps an engine control module that is that is designed to help an engine operate at its maximum efficiency. These features, as well as many more, depend on tiny semiconductors which are also known as computer chips to function correctly.

The chips are composed out of silicon. Silicon is obtained predominantly in Japan and Mexico and the majority of the production is done at China as well as Taiwan. They’re found in almost every electronic device that you can imagine that includes phones and video game consoles. They’re also used in laptops, televisions as well as the smart refrigerator that tells you your milk is due to run out.

How Did the Chip Shortage Begin?

In the first few months of the pandemic in 2020, when it was reported that the US along with its economies was largely shut down to stop the spread of Covid-19. Automakers and other businesses that are not essential were looking at a dark outlook, at least for the near term. If people were forced remain at home, and their incomes rapidly decreased and car sales were likely to fall. In anticipation of the tough times ahead, automakers reduced production shifts, laid off employees, as well as temporarily closed some factories completely. They also cancelled contracts with suppliers of parts since they didn’t anticipate the need for parts as vehicles weren’t being manufactured or sold.

As the disease spreads the schools have shifted to online education and millions of employees have logged at home from their homes to perform their job. The demand for consumer electronics, such as smartphones and laptops grew exponentially. Concerned about the movement of inventory, automakers gave buyers incentives, and together with dealers, moved to an online-based sales method and even offered home test drives and delivery.

It’s not surprising that consumers were on a shopping spending spree. Because most activities were limited to the home people and families did not have to spend money on daycare, take-away lunches, trips and even gym memberships. There was a growing desire for gaming systems as well as televisions and other electronic gadget that could keep kids entertained and parents healthy.

The increase in spending was evident across all sectors in the economic system, which included the auto industry. New vehicles were sellingwell, the inventory was shrinking because of factory shutdowns and transaction costs were increasing. Automobile companies were caught off guard , but were able to quickly return employees to their production facilities. They’d require to have a constant quantity of chips which were being allocated to other locations.

Thus the auto industry suffered an issue with semiconductor chips.

Impact of the Chip Shortage

Except for high-end models, cars that are in high demand as well as some limited-edition versions, US car sales have been buoyed by hefty incentives in recent times. Most often, these were large rebates and special financing deals with low rates. Dealerships were overflowing with inventory so much that they often had to lease lots in satellites to hold the ever-changing flow of vehicles and trucks arriving from factories. Making payments for the MSRP (Manufacturer’s Suggested Retail Prices) was not common.

The issue with chip supply has turned the scenario around. The CarGurus Vehicle Availability Index analysis conducted in May 2021 gives clear pictures of the way in which the US automobile market has evolved over the last year.

- The inventory of new cars is at 51.9 percent

- New car prices are on the rise by 5.7 percent

- Inventory at dealerships for used vehicles is increasing by 8.2 percent

- Inventory at used car dealerships is at a record low 7.4 percent

- Prices for used cars are rising 34.7 percent

- Days-on-market for used and new automobiles is down 38%.

The decrease in the number of new cars on the market is due to a variety of factors. The short-term production shut downs due to the pandemic resulted in that there was less inventory available after the flood of buyers returned. Additionally, the shortage of semiconductors compelled carmakers to change their focus. Businesses ranging from Mercedes-Benz up to General Motors (GM) took similar steps: allocate the small amount of chips to the most profitable cars. By not producing models such as those of the Chevrolet Trax and Mercedes-Benz C-Class they could concentrate on Tahoes that were loaded as well as S-Class sedans. As the inventory decreased the demand surpassed supply and prices increased. What did this mean? The incentives have been largely eliminated and buyers are willing to pay MSRP for more expensive models and automakers are making money despite selling less vehicles.

The buying frenzy also includes the market for used cars. The dealers are getting rid of every brand new car they can, but they need trade-ins from buyers, and are subsequently increasing in value. In the past, dealers could have offered low prices for these vehicles, or sold them to used car dealers, but they’re selling them with a nice profit. Private owners who are looking at their vehicle which has risen to the point of being worth more, are now entering the market to earn top value for their car through either selling or trading in their new car.

Responses to the Chip Shortage

Additionally, they use the rare semiconductor chips that are used in high-end automobiles, GM and Ford are two major automakers that have been able to keep production running for their most popular vehicles and SUVs. The tens of thousands of fully functional Ford F-150s and Chevrolet Silverados are parked in facilities across the nation still waiting to be equipped with chips which will make them functional and ready to be delivered to dealers. Automotive News has revealed that Ford is looking at shipping the F-150s to dealers in which technicians will finish the final installation of chips.

In some cases automakers are also announcing that the vehicles won’t being sold with specific features. GM for instance, has stopped offering the automatic engine stop-start option or HD radio on certain Chevrolet Silverados models, and has pulled the plug on wireless chargers for smartphones from various crossovers and SUVs.

Lessons to be learned through the Chip Shortage

It’s unfortunate that no one has yet come with a solution immediately for the problem of the shortage of semiconductor chips however, efforts are being taken to ensure that this doesn’t happen again. According to Fortune, German automakers are developing an alert system for cloud-based systems which will alert them to possible disruptions to the supply chain. Others are working towards the same end by increasing communication with not just directly-suppliers as well as the sub-suppliers who might be the best for alerts in the early stages.

Also, attention is being paid on the supply levels. To increase efficacy, some carmakers utilize the lean-inventory method, meaning that parts are brought in when they’re needed to support the vehicle production. A reserve or stockpile of semiconductor chips could be beneficial in this instance.

As one could imagine, there’s been lots of talk about diversifying supply chains. The chipmaker Taiwan Semiconductor reported that it will increase its capacities by 60 percent, however there is a strong drive to develop semiconductors and other crucial components at home in the US. President Biden has suggested investing $50 billion in the initiative.

The Bottom Line

Covid-19 has highlighted how important it is to have the capacity to adapt. Families and individuals were forced to adapt just as government and businesses. Consumers are still buying cars, though usually at higher costs and without their preferred features.

The most interesting conclusion is that mainstream automobile manufacturers have found ways to boost profits by constructing and selling fewer automobiles. In order to do this they’ve focused their efforts on providing the smallest number of highly equipped vehicles that are sold without discount. For now at the very least, customers are lined up to purchase the models.

Alex has been with us from the start, providing readers with the latest news and comprehensive reviews. Her extensive knowledge of the automotive industry makes her an invaluable asset to the team.